Product display

Contact Us

Address: Middle Street, SME Pioneer Park, Zaoqiang County, Hebei Province

Tel:+86-15132818341

E-mail:664609813@qq.com

QQ:664609813

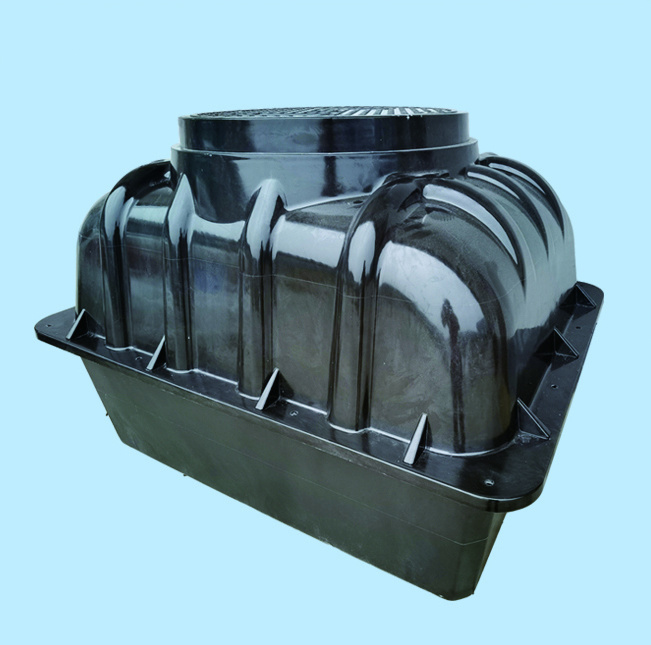

SMC Cable Trough Box for Railway

Our products mainly include: water meter wells, valve wells, manhole covers, glass fiber reinforced plastic water canals, drainage ditches, high-speed jet tanks, glass fiber reinforced plastic cable supports, glass fiber reinforced plastic cable trays, SMC fire tank boxes, septic tanks, fire prevention boards, bird prevention covers, anti-glare boards, glass fiber reinforced plastic grids, glass fiber reinforced plastic pipes, BWfrp power pipes, glass fiber reinforced plastic pultrusion profiles and other series of glass products, as well as special-shaped products with grinding tools.

Key words:

SMC Cable Trough Box for Railway

Classification:

Product Description

Production and manufacturing process of railway SMC molded cable trough and its performance advantages? The production and manufacturing process of railway SMC molded cable trough adopts SMC composite molding process.

1. Environmental protection and green

SMC composite material is a kind of non-halogen, no harmful substances, is a new type of environmental protection material, to meet the needs of future green development.

2. Chemical corrosion resistance

SMC composite materials have good corrosion resistance to acid, dilute alkali, salt, organic solvents, seawater and other corrosion characteristics, while metal materials are not acid-resistant and easy to corrode.

3. Light weight and high strength

Specific strength and specific modulus are one of the indicators to measure the carrying capacity of materials. The specific modulus of SMC composites is equivalent to that of steel, but its specific strength can reach 4 times that of steel.

4. Good fire retardant performance

SMC composite materials are fireproof and flame retardant; The material is tested as Class B incombustible material by the national * * * organization.

5. Good heat resistance

SMC composites have the ability to maintain their physical properties in harsh high-temperature environments, with a working temperature of minus 60 degrees to 150 degrees and a thermal deformation temperature above 280 degrees.

Zaoqiang Mingxuan FRP Co., Ltd. is located in Zaoqiang County SME Pioneer Park, which is known as the "Hometown of China's FRP Production". In order to meet the needs of the vast market, our company adheres to the concept of responding to the call of the country and is established under the opportunity of China's rapid economic development. A technology enterprise, the company has always taken product independent research and development and manufacturing as the leading ideology, innovative products as the leading force, and user demand as the development direction, focus on glass steel molding product research and development design, production, sales as one. The company's production capacity product quantity, design level, quality standard, promote the overall industry level.

Our products mainly include: water meter wells, valve wells, manhole covers, glass fiber reinforced plastic water canals, drainage ditches, high-speed jet tanks, glass fiber reinforced plastic cable supports, glass fiber reinforced plastic cable trays, SMC fire tank boxes, septic tanks, fire prevention boards, bird prevention covers, anti-glare boards, glass fiber reinforced plastic grids, glass fiber reinforced plastic pipes, BWfrp power pipes, glass fiber reinforced plastic pultrusion profiles and other series of glass products, as well as special-shaped products with grinding tools. The company has established a sound quality management system, passed the quality inspection department of various aspects of testing, complete quality control and testing system to ensure the stability of product quality.

The company will adhere to the development goal of "technology-based, perfect management, satisfactory service and sustainable development", continue to increase R & D investment, optimize product structure and improve product performance, so as to improve the technical content of products and strive to be a technology research and development enterprise. In terms of service, the company will, as always, adhere to the business philosophy of customer first, constantly improve the level of customer service, and improve customer loyalty. In terms of development, the company will adhere to the development goal of continuous research and development, adapt to environmental changes for technological research and development, continue to develop the market, and strive to become a well-known and powerful manufacturer.

We sincerely hope to cooperate with new and old customers at home and abroad on the basis of mutual benefit, friendly cooperation, and establish a good cooperative relationship. Welcome people from all walks of life to guide our company and create a better future!

Workshop

Pre

Next

Pre

Polyurethane bridge

Next Page

Related Products

Consultation